About a year or so after I got the car running, a reporter from the newspaper contacted me. A coworker of mine called the paper and they came out to do a story. About 9 months later the article showed up in the paper. The reporter had absolutely zero technical background and was not interested in anything technical about the car which was the complete opposite of my interest when building the car. I was not sure how well he would do writing an article about this car, but in the end I think it turned out ok. It’s definitely a human interest piece and not a technical piece.

——————————————————————————–

Originally published Monday, October 11, 1999

——————————————————————————–

Electric avenue

By Christopher Lewis

Record Staff Writer

Rule No. 1 in the as-yet-unwritten guide to driving an electric-powered car: Watch out for pedestrians in parking lots.

If you think they’re oblivious now to cars backing out of parking spaces, just wait until they can’t hear you.

Pulling out of his driveway one afternoon, Michael Palmer of Stockton demonstrated how he’s spooked a few innocent bystanders. He turned the key in his 1974 Porsche 914 and … nothing but dead silence.

Instead of vroom-vrooming to life, the car sounded like it had a dead battery. Actually, the little bugger had 21 juiced-up batteries rarin’ to go.

Like a kid working on a school science project, Palmer, 31, kept his electrical creation a secret during three years of garage tinkering. Friends and co-workers were positively electrified last month when he unveiled the Porsche during his daily commute.

“They thought I was nuts,” Palmer said. “But the reaction so far has been all positive.”

He thought the revamped car might anger Porsche purists. But the 500-amp motor, which ran effortlessly at 250 amps (about 70 mph) during a quick test spin on the Crosstown Freeway, has almost as much muscle as the original 75-horsepower engine. All for about 4 cents a mile.

“If this was a company project, he’d have a bonus that would support you and me,” said co-worker Bob Reynolds of Franrica Food Tech in Stockton, where Palmer works as an automation engineer on food-processing equipment.

“I was totally amazed,” Reynolds said. “The only noise it made was the tires on the pavement.”

Palmer’s Porsche didn’t have an engine when he bought it, either. He paid less than $500 for the beat-up frame lounging in Brent Berkebile’s front yard in west Stockton, looking like junked leftovers from a teenage gang’s Saturday night strip show.

Palmer had her towed home and dressed her up. He painted the exterior black and yellow and installed a fiberglass convertible roof.

“(Brent) kept calling me up — ‘Do you want these engine parts?’ ” Palmer said, chuckling mischievously.

Berkebile, who works at Martini’s Auto-

motive, said Palmer showed up at his house unannounced last month.

“I was eating dinner and I didn’t hear anyone (drive) up,” Berkebile said. “I thought he was just going to put a fuel-injected, 2-liter Porsche (engine) in it. I looked underneath and I said, ‘Kind of quiet, isn’t it?’ ”

He was impressed with the car’s performance. “It has a lot of pickup,” Berkebile said.

Perhaps the biggest perk is the running list of headaches Palmer can do — actually does — without: no more tuneups, valve adjustments, oil changes, radiator leaks, busted fan belts … (insert your own “no more” here). Replacing the batteries every five to six years for a total of about $1,000 is still a bargain compared to regular car maintenance, he said.

And smog checks? Puh-leeze. That’s, like, so 20th century.

The state Department of Motor Vehicles was impressed — they gave Palmer’s ride a clean bill of health and new registration.

“They just flipped out,” he said.

Palmer may blow off smog checks, but his electric car has a few reality checks. The motor doesn’t have quite the same kick going up hills, in part because the batteries pack an extra 300 to 400 pounds.

The main roadblock is the limited range — the car can go a maximum of about 100 miles before recharging. A full recharge takes about eight to 10 hours. But Palmer carries an extension cord in the trunk so he can conveniently plug in to a standard 110-volt outlet wherever.

The car runs on 20 six-volt traction batteries more familiar on putting greens than roadways. Golf carts typically run on four to five such

batteries. A smaller battery powers the radio, headlights and blinkers.

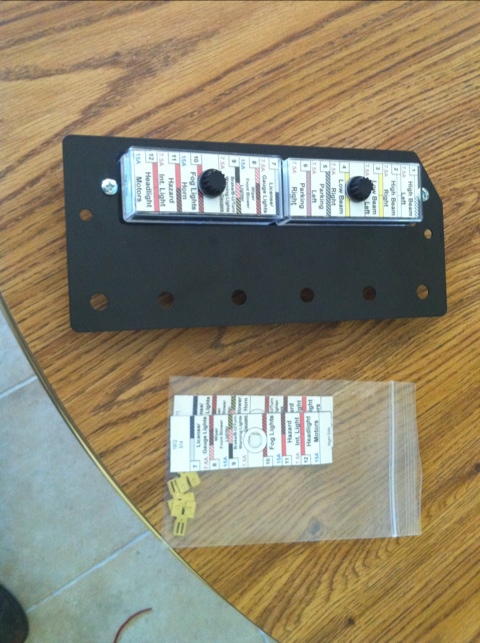

Besides the speedometer, the only instruments Palmer relies on now are the palm-sized volt and amp meters.

Several local government agencies employ electric vehicles, but they’re struggling to dent the mass market because of the high cost. The cities of Lodi and Stockton, which are exploring grants to lease electric cars, might get a charge out of Palmer’s Porsche. He researched electric cars on the Internet and purchased $5,000 worth of parts from Bay Area and Arizona companies.

The Porsche isn’t Palmer’s first project. He worked on a solar-powered car while he was a student at California Polytechnic State University. And his mountain get-away is a 1968 Ford Bronco he restored after college with a digital dashboard and computer-controlled engine.

He’s got wheels for each of the four decades he’s lived in — the Bronco, the Porsche, a 1987 Toyota Corolla (possibly his next electric venture) and a 1991 Corvette.

But the Porsche is the jaw-dropper when Palmer rolls to a stop at intersections.

“People just turn their heads and look at me funny,” Palmer said. “They are curious. Most of them have never seen an electric car. They want to know all about it.”